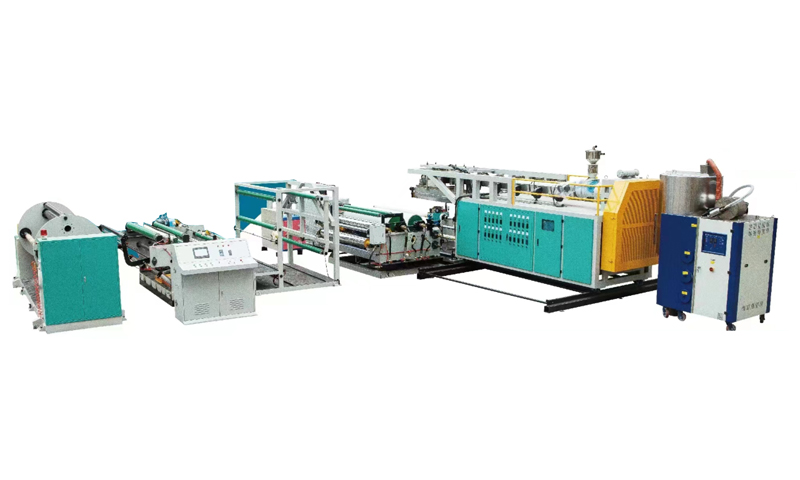

CPE Multiple Layer CO-Extrusion Cast Film Production Line

Production Line Features

Production Line Characteristics

1)Screw structure with a unique blending function and high plasticization capacity , excellent plasticity, effective mixing, high productivity;

2)Selectable fully automated T-die adjustment and equipped with APC control automatic thickness gauge, online measurement of film thickness and automatic T-die adjustment;

3)Cooling forming roll designed with a distinctive spiral runner, ensuring optimal film cooling during high-speed production;

4)On-line recycling of film edge material, leading to significant reduction in production expenses;

5)Automated center rewinding, equipped with an imported tension controller, allowing for automatic roll change and cutting, facilitating effortless operation.

The production line is mainly used for the production of three layers of co-extruded CPE and CEVA film.

Product Application

2. Everyday essentials: waterproof coat, rain umbrella, dining table covering, suit bag, hand protection, cooking apron, bathtub curtain, shower cap, and so forth.

3. Wrapping materials: PC case, household appliance protector, shoe shield, soft beauty package, carrying bag, present pouch, record holder, file protector, and the like.

Technical Data

|

Finished Width |

Finished Thickness |

Mechanical Design Speed |

Stable Speed |

|

1600-2800mm |

0.04-0.3mm |

250m/min |

180m/min |

Please contact us for more machine technical datails and proposal. We can send you machine videos for clear understanding.

Our Service

Technical Service Promise

The machinery undergoes testing and trial production using the raw materials prior to its shipment from the factory.

We are accountable for the installation and adjustment of the machines, and we will provide training to the buyer's technicians on the operation of the machines.

During the span of one year, in the event of any major parts failure (excluding breakdowns caused by human factors and easily damaged parts), we will be responsible for assisting the buyer in repairing or replacing the parts.

We will provide long-term servicing for the machines and regularly dispatch workers for follow-up visits to aid the buyer in resolving significant issues and maintaining the machine.

Workshop and Machine

Customer's Production Field