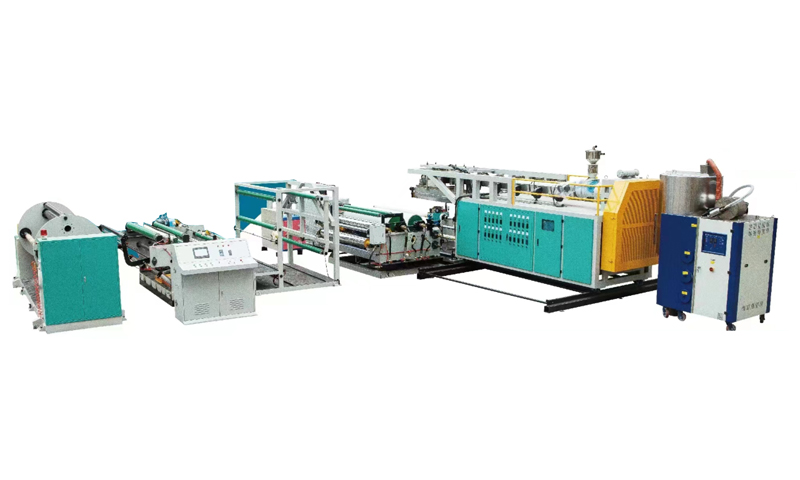

CPP Multiple Layer CO-Extrusion Cast Film Production Line

Production Line Features

1)Screw design with a special mixing function and high plasticizing capacity , good plastic, good mixing effect , high output;

2)Optional full automatic adjustment T- die and with APC control automatic thickness gauge , online automatic measure the film thickness and automatic adjust the T-die;

3)Cooling forming roll with a special spiral runner design , make sure good film cooling effect at high speed production;

4)Film edge material directly on-line recycling. greatly reduce production costs;

5)Automatic center rewinding, with imported tension controller, automatic change the roll and cut off, the operation is very simple.

The production line is mainly used for the production of three layers of co-extruded CPP film.

Product Application

1)Hygiene products: sanitary napkin, lady pad, baby diaper, medical surgical gown, pet cushion, disposable underpad and etc.

2) Daily necessities: raincoat, umbrella, tablecloth, western style suit cover, glove, apron, bath curtain, bath hat and etc.

3) Packaging: computer cover, electric appliance cover, shoes cover, cosmetic soft package, shopping bag, gift bag, document folder, file cover and etc.

Technical Data

|

Finished Width |

Finished Thickness |

Mechanical Design Speed |

Stable Speed |

|

1600-3500mm |

0.02-0.15mm |

250m/min |

180m/min |

Our Service

Technical Service Promise

1) The machine are tested with the raw materials and have a trial production before machine shipping out from factory .

2) We are responsible to install and adjust the mahcines ,we will train the buyer's technicians about mahcine operation .

3) One year's warranty :during this period ,if there is any key parts breakdown (not included cause by human factors and easily damaged parts),we are responsible to help buyer to repair or change parts .

4) We will offer the lifelong service to the machines and send workers to pay a return visit regularly,help buyer to solve major problems and maintain the machine.

Workshop and Machine

Customer's Production Field