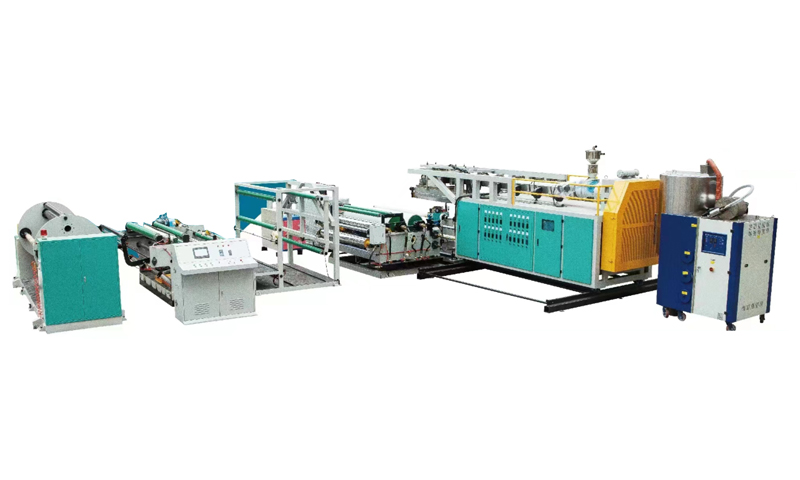

High Speed PE Sanitary Product Cast Film Machine

Note

1)It is integrated with unwinding, fabric heating, casting, laminating, edge trimming, scrap suction, rewinding.

2)Photoelectric web guider is used for tracking, digital electronic device automatic meter counter;

3)Advance technology of constant tension control, temperature automatic control

4)Applicable raw materials: PE, EVA, TPE, POE

5)The layers of laminating can accord to buyer’s demand, we offer solution for single layer, double layers, and triple layers.

6)We offer different systems to meet different demands, such as surface friction winding, automatic turret winding etc.

Application

This machine can produce LDPE, LLDPE, HDPE, EVA etc. casting film,products widely applies in baby diaper, lady napkin backsheet film.adult diaper film, pet pad film, surgical gowns, disposable bed sheet etc, medical products field.

Technical Data

|

Finished Width |

Product Width |

Machine Design Speed |

Production Speed |

|

1200-3300mm |

13-35g/m² |

180m/min |

130m/min |

| Optional choice for Automatic thickness gauge, automatic flaw detect, automatic T-die | |||

| The finished width can according to customer’s requirement to customized | |||

| It can realize online laminating function | |||

Please contact us for more machine technical datails and proposal. We can send you machine videos for clear understanding.

Our Service

Technical Service Promise

1) The machine are tested with the raw materials and have a trial production before machine shipping out from factory .

2) We are responsible to install and adjust the mahcines ,we will train the buyer's technicians about mahcine operation .

3) One year's warranty :during this period ,if there is any key parts breakdown (not included cause by human factors and easily damaged parts),we are responsible to help buyer to repair or change parts .

4) We will offer the lifelong service to the machines and send workers to pay a return visit regularly,help buyer to solve major problems and maintain the machine.

Workshop and Machine

Customer's Production Field